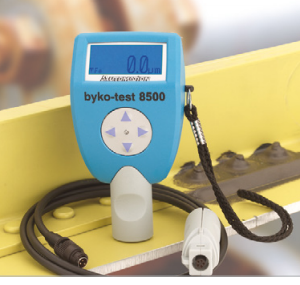

Dry Film Thickness Gages

Paint thickness is an essential parameter that needs to be measured routinely. The proper film thickness has an impact on the paint opacity, appearance, and protective properties of the coating. Applying too much coating can also be detrimental that can lead to excessive dry time, cracking, and flaking of the paint film. Coating thickness measurement will monitor the paint process and maintain the appropriate coating properties. Paint thickness gauges for dry film thickness can either be a non-destructive measurement or destructive measurement. The non-destructive paint gauge uses measurement principle of magnetic induction for ferrous substrates and eddy-current for non-ferrous substrates.

Showing all 4 results